Made in Yorkshire: Carbon Engineered Excellence

Carbon Wasp – artisans for the modern era

by Robert Thorpe & Ben Thorpe (images)

If you look hard enough across the internet, you’ll find a wealth of small and specialist engineers making bikes and bespoke bike parts in small workshops up and down the U.K… Here in Yorkshire, there’s a history of stell frame building within cycling, from the likes of Bob Jackson in Leeds to Ellis Briggs at Shipley, and the legendary Arthur Caygill at Richmond. Yes, Yorkshire cyclists have been going to these hidden places for over a hundred years, having their own unique steel framed bikes crafted for these artists of engineering.

And so, it should come as no surprise that in the modern era of lightweight carbon bikes, that there’s now a growing trend in ‘small is beautiful’ experts, quietly working away and practising the art of frame building, but instead of steel, now using this most modern of materials. Leading the way, tucked neatly behind Station Road near the train station in Horsforth, is Adrian Smith and his small team at Carbon Wasp. Adrian and the team already have some great success stories behind their work, with riders having won world titles using their products in a variety of disciplines, especially on the track and time-trialling, where his bespoke and fitted aero-bars have won a renowned reputation and numerous medals globally. Not bad for a small workshop in Leeds.

Building a future from Carbon

One area of work that keeps Adrian and the team busy are repairs to carbon bikes – both road and mtb. The most common areas for faults and cracks are seemingly the seat stays, where the rear mech can flip and cause damage, and the seat posts. Whilst we were there, just a few weeks before Christmas, he had an early 1990s version of the famous Lotus TT bike waiting for repairs. Looking at this early carbon racer, Adrian pointed out the framework and how carbon engineering had moved on in the subsequent 30+ years. Whilst the shaping and aerodynamics were ground breaking, the seat post looked like an afterthought.

As Adrian indicated, the amount of filler used in areas of the frame, and then the not so well considered seat post, which looked as though they’d been down the pub after producing the world’s most radical bike frame and suddenly realised ‘Oh heck, we haven’t created a seat post!’ Yes, carbon engineering has moved on considerably, and is far stronger and so much more reliable in the new millennium. There’s a whole variety of frames hanging up in the workshop, all awaiting their own repairs and adjustments; quite simply, repairing your pride and joy is now far easier than you’d imagine, thanks to the skilled hands of people like Adrian – but the real excellence comes in what he designs and produces, and not what he repairs.

Carbon Wasp MTB

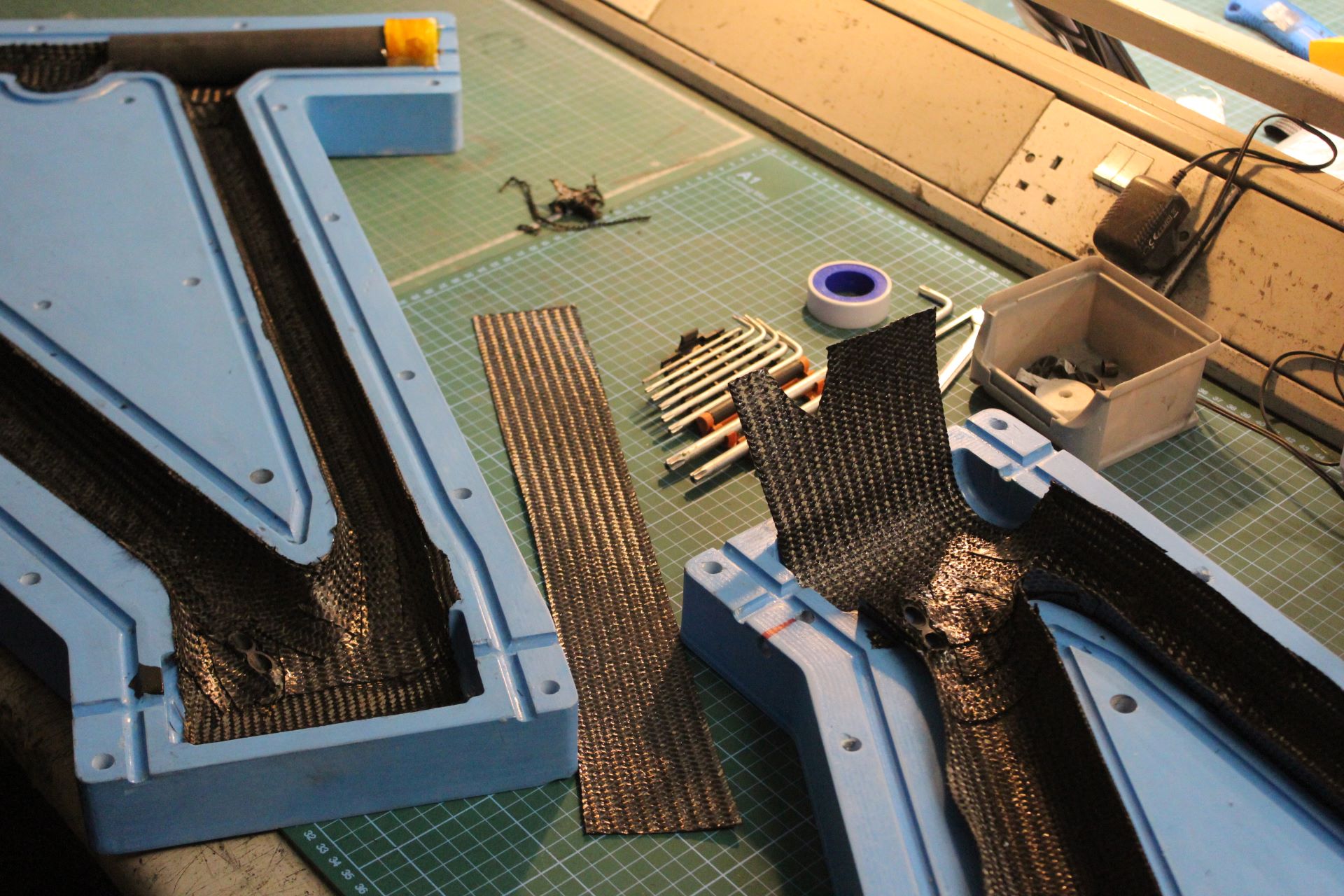

Sitting quietly and leaning against a workbench, we spied the latest version of the Carbon Wasp Mountain Bike. The Carbon Wasp Truffle 120 frame is designed to be built into a bike for all occasions. With 120mm of plush and progressive rear travel, combined with a strong and stiff carbon frame to get you efficiently to the top of the trails so you can get rowdy on the way back down, it’s an aggressively engineered bike that wants to take on the trails and speed its way around the hills.

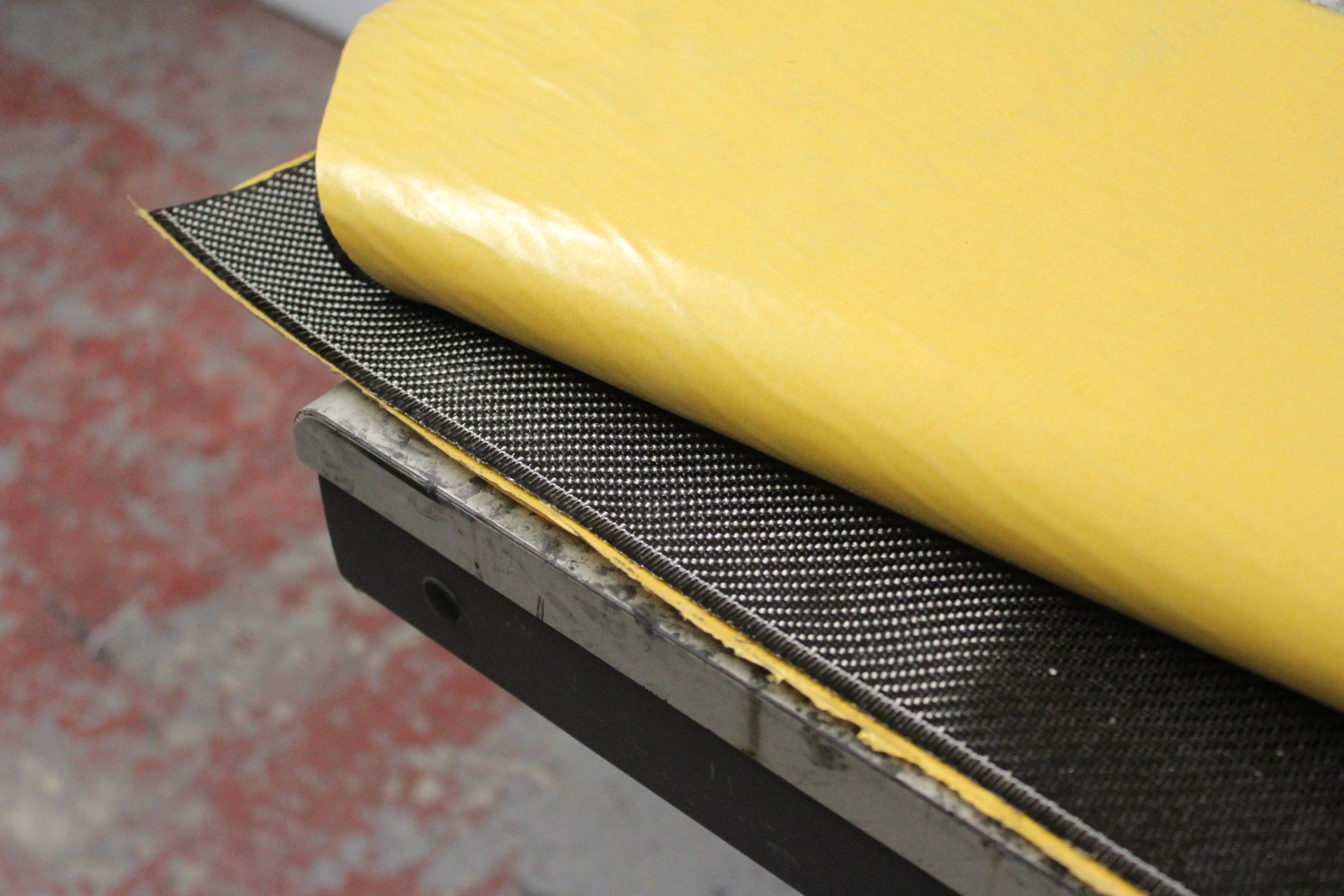

The previous iterations of this amazing looking frame are scattered on the shelves of the workshop, whilst future versions line the frame moulds on the workbenches, as skilled hands placed the carbon fabric and neatly trim everything by hand, before the moulds are set and the finished frame emerges into the world. All of their frames are made by hand in this small workshop in Leeds, UK, using the finest pre-preg carbon fibre. Coming from a mountain biking and race background, and being an engineer who is always thinking ‘I wonder…’, Adrian enthuses about the process of using carbon in bicycle design, and it becomes obvious that it was this passion that led him into wanting to personally produce the very best carbon bike himself – carrying on that historic Yorkshire tradition of engineering excellence in cycling.

Off the peg is old hat – try something special

With the prices of bikes rising across the global cycling industry, we’re all looking for that something special in our own new purchase; and we ought to be able to get something that’s built just for us too. Being a rider with my own custom-built bikes at homes, there’s something quite nice about choosing the frame, the wheels, the fork and the finishing kit, all to your own needs and specifications. After all, you’re paying a whole lot of money, and this is Yorkshire after all! A new Carbon Wasp Truffle 120 bespoke carbon frame will cost you less than £3k (Dec 2024), making it excellent value. Better still, it drops considerably if you’ve got your own rear shock. Then, you can build up the bike that you’ve always dreamt of, and ride the hell out of the trails, at home and abroad, on a bike that’s been designed and built by hand here in Leeds, by craftsmen.

Or, if you’ve managed to have a mishap on your current carbon road or trail bike, and you’ve been scared about the cost of a repair, having been frightened off by the retailer who simply wants you to buy a new bike; then give the guys at Carbon Wasp a call or send an email and let them work their magic in bringing your trusty steed back to life at a reasonable price point.

Yes, hidden away within the workshops of the U.K. and elsewhere, there’s a small and gifted cadre of craftsmen taking the art of bicycle design to new levels, using the most modern of materials in new ways, producing cycling excellence for riders who want the very best – isn’t it time that you joined the revolution!