What is the best carbon road bike frame in the world?

TIME to find out

by Robert Thorpe & Nadezhda Pavlova

It’s a complex question, I know, as there are so many carbon bike frame manufacturers out there in the world. Many of them are based in the Far East, where they’ve become world experts at creating high-performance, high-quality carbon frames using techniques such as monocoque, which involves the layering of pre-peg carbon sheets around a mold and using an inflatable bladder for a seamless structure. However, in truth, that’s a rudimentary, old-fashioned and simplistic way of producing a frame these days. It helps the larger multinational brands to produce in volume, yes; but does it produce the most innovative, strong, light, responsive and performance orientated frameset – probably not.

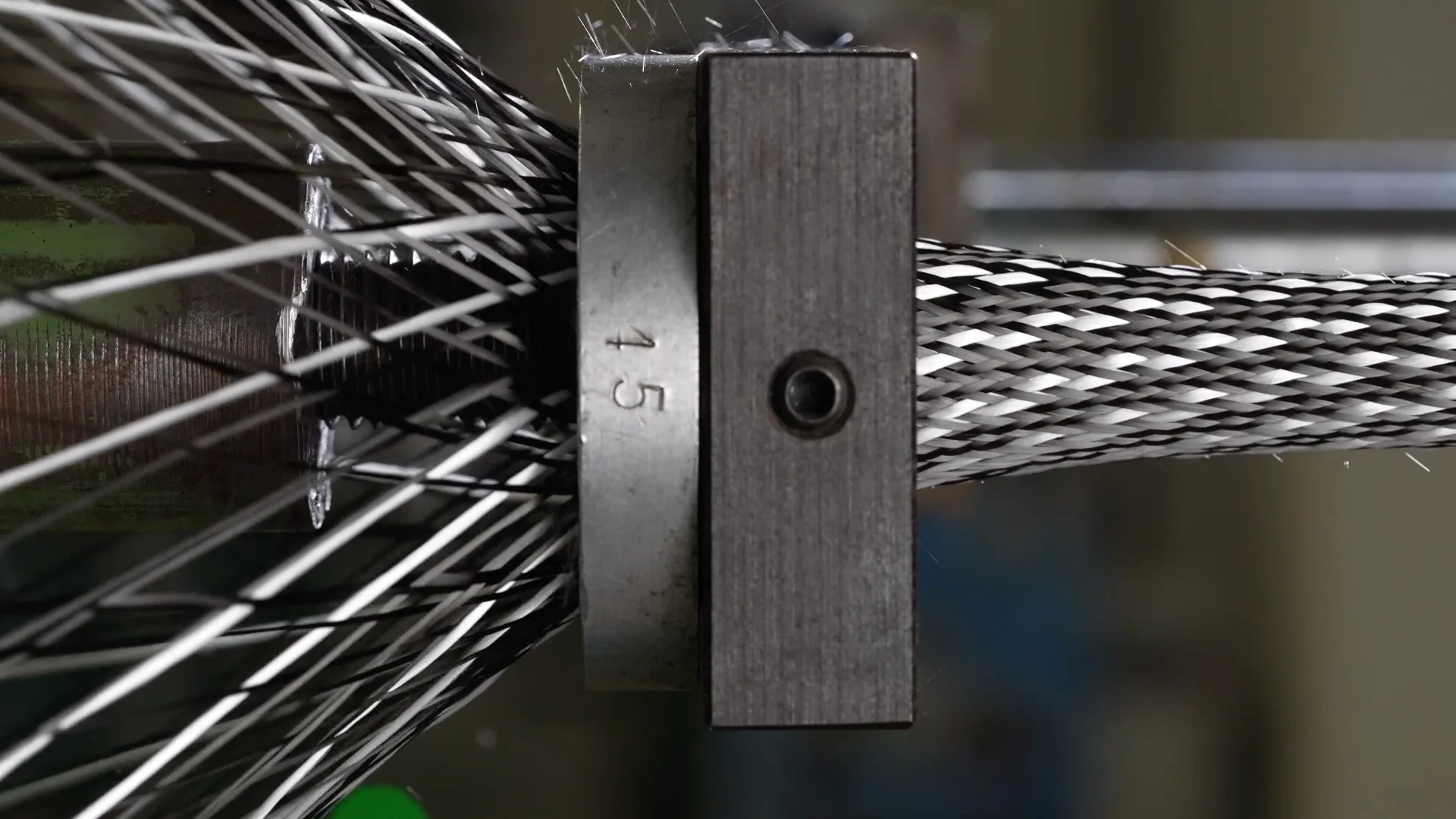

Some brands use the Holo Core methods, where foam cores are removed after curing framesets. However, in certain corners of Europe, brands such as TIME and 3T are creating woven carbon framesets, using their own developed techniques, such as TIME with its Braided Carbon Structures (BCS) and Resin Transfer Molding (RTM).

Braided Carbon Structures

Braided Carbon Structure is a technique that involves the weaving of multiple different fibres into complex bi-directional ‘socks.’ These carbon woven tubes are easy to tune with different materials, dependent on what is required from each individual bike model, and how tests have been carried out to determine which works best. TIME for instance, who have perfected the BCS technique over more than 20 years, currently chose from 16 filaments to perfectly tailor their layups.

Using the Braided Carbon Structure technique, from their artisan factory near Bratislava in eastern Europe, this iconic cycling brand has refined a process that allows something that is unheard of in the cycling world: continuous, unbroken fibres that run the full length of a carbon frameset structure. Think about this for one moment; not layered pieces of carbon cloth, but one long, unbroken and seamless sock of woven fibres. It’s easy to imagine the integrity of many layers of uninterrupted woven fibres running through a steerer tube and being integrated into a fork crown, and even down the fork legs with minimal overlapping joints. Contrast this technique with the industry standard prepreg layup where the edge of every carbon sheet is a potential weakness, and you begin to get the answer to that question posed at the start: what is the best carbon road bike frame in the world?

TIME SCYLON – probably the most beautiful carbon road bike in the world

The answer, for us here at Pedalnorth at least, is easy to determine. When you see a TIME SCYLON frameset being finished by the craftsmen and women in Slovakia, then the answer is this: TIME design and create the best carbon bikes in the world. They produce works of engineering art – not in huge numbers, because that would dilute things. They take their time to ensure that a TIME road bike looks as good as it rides – which is exceptional. The TIME SCYLON -the bike of choice for our editor and colleague, Nadezhda, is probably the most responsive and comfortable high-performance road bike in the world.

TIME engineers spent almost 2 years agonizing over every detail of the 2025 SCYLON release. Producing the best aero bike in the world does literally take TIME… pardon the pun. These artisans and engineering gurus wanted to ensure that the balancing of these key elements: aerodynamics, weight, responsiveness and comfort whilst challenging, was ultimately given the detail required if they were to produce the world’s best bike in its class.

When you are working to increase stiffness and tube sizes, it can also increase weight, whilst narrowing frontal areas for that all-important aero shaping can affect overall performance and ride quality. This needed a detailed focus, with absolutey nothing left on the table 2 years later. The result is a bike that glides along the road and produces the ultimate experience in cycling – a perfect balance between performance and pleasure.